dot hardness testing procedure pdf|hardness test results : import from a hardness test can be used to provide critical material performance information and insight to the durability, strength, flexibility, and capabilities of a variety of component types from raw materials to prepared specimens, and finished goods. Hardness testing is widely used in a multitude of industries and plays particular significance . Acompanhantes mulheres em Ibiúna - SP | Fatal Model. Ibiúna - SP. Mulheres Homens Trans. Ordenar. Filtrar (0) Ingrid Nynffa. Offline há 3 semanas. Putinha Sub e Domme .

{plog:ftitle_list}

Resultado da BrxBet é o melhor site de apostas esportivas, com diversas opções de esportes para apostar e promoções exclusivas. Com uma plataforma .

Scope* 1.1 These test methods cover the determination of the Rockwell hardness and the Rockwell superficial hardness of metallic materials, including test methods for the verification of machines for Rockwell hardness testing (Part B) and the calibration of standardized hardness test blocks (Part C). 1.2 Values stated in inch-pound units are to be.Principle of Test. The Rockwell test consists of measuring the additional depth to which a carbide ball or Brale® diamond penetrator is forced by a heavy (major) load beyond the depth of a previously applied light (minor) load (SET point).from a hardness test can be used to provide critical material performance information and insight to the durability, strength, flexibility, and capabilities of a variety of component types from raw materials to prepared specimens, and finished goods. Hardness testing is widely used in a multitude of industries and plays particular significance .The principle of rockwell hardness test Rockwell hardness measurement method is to use rules of pressure head, two trials in successively applied (early test force Fo and total test force F), the pressure into the surface of the sample, the total test force to maintain a .

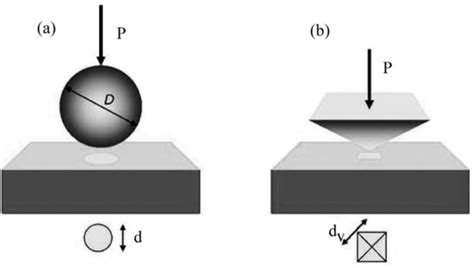

The Brinell hardness test involves indenting a material with a hard sphere under a specific load. Two diameters (x and y axis) of the indentation are measured, and the hardness value is determined based on the load applied. Brinell belongs to the optical methods.1.1 These test methods cover the determination of the Rockwell hardness and the Rockwell superficial hardness of metallic materials by the Rockwell indentation hardness prin-ciple. This standard provides the requirements for Rockwell hardness machines and the procedures for performing Rock-well hardness tests. The purpose of this Guide is to explain the causes of variability in Rockwell hardness test results and to supplenment the information given in test method standards with good practice recommendations.The 3831Digital Rockwell Hardness Tester can be used directly to measure the most popular regular Rockwell hardness scales and it can quickly convert that hardness value into HB, HV, HLD, HK and many other scales.

This document contains test procedures for quantitative and comparative analysis of Rockwell hardness on metal evidence. To evaluate a surface hardness gradient (e.g., due to carburizing or. Loads of Different Hardness Test Methods. Each hardness testing method has a range of loads that are applicable to the use of the test. Some tests, like the Vickers hardness test, can be used on a macro scale as .

willrich hardness testing distance

The hardness of a material by this Rockwell hardness test method is measured by the depth of Penetration of the indenter. The depth of Penetration is inversely proportional to the hardness. Both ball or diamond cone types of indenters are used in this test. There are three scales on the machine for taking hardness readings.In the Rockwell hardness test, a differential-depth method, the residual depth of the indent made by the indenter, is measured.In contrast, the size of the indentation is measured in the Brinell, Vickers and Knoop optical test .Hardness testing is widely used in a multitude of industries and plays particular significance in structural, aerospace, automotive, quality control, failure analysis, and many other forms of . Rockwell testing is the most commonly used method by virtue of the quick results generated and is typically used on metals and alloys. It generates a .Indentation hardness value is obtained by measuring the depth or the area of the indentation using one of over 12 different test methods. Learn more about hardness testing basics here. The Rockwell hardness test method, as defined in ASTM E-18, is the most commonly used hardness test method. You should obtain a copy of this standard, read and .

To make a hardness test, just press the button on the impactor while holding it against the workpiece surface. It is . easy and user-friendly. Optional accessories Order No. Description Remarks: Q'ty 264-504-5A: Digimatic Mini-Processor DP-1VR: 1: 937387: Connecting cable For DP-1VR and display unit: 1: 3.1.10 portable Brinell hardness testing machineÐa Brinell hardness testing machine that is designed to be transported, carried, set up, and operated by the users, and that measures Brinell hardness by the Brinell hardness test principle. 3.1.11 movable Brinell hardness testing machineÐa Brinell hardness testing machine that is designed to be .

Test Procedure Test procedure consists of a preload of the specimen using the force of the elevation screw and a test load using the weights. 1. Mount specimen on required anvil. Rotate the elevation screw threaded collar clockwise slowly until .to Brinell hardness 25-135HBW. Used to test the hardness of all kinds of aluminum, from very soft pure aluminum to very hard aluminum alloys; Extended application. Model 934-1 is applied to test the hardness of aluminum, aluminum alloys, copper, copper alloys, fiber reinforced plastics and rigid plastics etc. The modified models of it are .When reporting hardness, state the method used, for example, “hardness (calc.)”or “hardness (EDTA).” 2340 B. Hardness by Calculation 1. Discussion The preferred method for determining hardness is to compute it from the results of separate determinations of calcium and magnesium. 2. Calculation Hardness, mg equivalent CaCO3/L

ISO 6508-2:2015(E) 4.3.2 The instrument or gauge blocks used to verify the depth-measuring system shall have a maximum expanded uncertainty of 0,000 3 mm when calculated with a 95 % confidence level. 4.3.3 Calibrate the testing machine’s depth measurement system at not less than four evenly spaced increments covering the full range of the normal working depth .2 A procedure covering Vickers tests using applied forces of 1 gf to 1000 gf (1 kgf) may be found in Test Method E 384, Test Method for Microindentation Hardness of Materials, appearing in the Annual Book of ASTM Standards, Vol 03.01. 3 Annual Book of ASTM Standards, Vol 03.01. 1Brinell hardness tests are considered satisfactory for accep-tance testing of commercial shipments, and they have been used extensively in industry for this purpose. A. GENERAL DESCRIPTION AND TEST PROCEDURE FOR BRINELL HARDNESS TESTS 5. Apparatus 5.1 Testing Machine—Equipment for Brinell hardness test-ing usually consists of a testing .

The ease with which the hardness test can be made has made it the most common method of inspection for metals and al-loys. Why so valuable? Principally, the importance of hardness testing has to do with the relationship between hardness and other properties of material. For example, both the hardness test and the tensile test measure the .Hardness testing within the realm of materials testing. Today, hardness testing is one of the most widely used methods in mechanical materials testing, especially for metals. On the one hand, this test method can be used to find .

indentation hardness testing

Standard Operating Procedure AMBL-104-A Hardness by EDTA Titration METHOD SUMMARY This SOP describes the procedure for measuring hardness by titration with standard EDTA solution to endpoint indicated by a color change. This method is based on Method 2340 C of Standard Methods for the Examination of Water and Wastewater , 22 nd Edition.

Working Procedure – Rockwell Hardness Testing Machine Working Procedure – Rockwell Hardness Testing Machine 1) Check - Level of Machine should be proper. 2) Check - Machine should be in unload condition. 3) Check - Indenter Placement. 4) Check - Dial’s hands should be stationary. 5) Select - Proper Indenter according to Table A.

an automatic hardness testing machine where the hardness is determined auto-matically. Depending on the size of the applied load, the indentation hardness test can be divided into macro (also called gen-eral or universal) and micro hardness testing. For macro hardness testing, the test loads are 1 kgf (9.81 N) or larger, Rockwell hardness testing machine that is designed to be transported, carried, set up, and operated by the users, and that measures Rockwell hardness by the Rockwell indentation hardness test principle. 3.1.7.4 movable Rockwell hardness testing machine a Rockwell hardness testing machine that is designed to be©ISO ISO 6508-1:1999(E) iii Foreword ISO (the International Organization for Standardization) is a worldwide federation of national standards bodies (ISO3.1.4 Rockwell superficial hardness test—same as the Rock-well hardness test except that smaller preliminary and total test forces are used. 3.1.5 verification—checking or testing to assure conform-ance with the specification. 4. Significance and Use 4.1 The Rockwell hardness test is an empirical indentation hardness test.

Vickers Hardness Test The Vickers hardness test method consists of indenting the test material with a diamond indenter, in the form of a right pyramid with a square base and an angle of 136 degrees between opposite faces subjected to a load of 1 to 100 kgf. The full load is normally applied for 10 to 15 seconds.

Do not test any specimen that cannot be safely and properly positioned on and supported by the tester anvil. Operation: Determine the proper indenter, scale and weight for the material hardness to be tested (see last page in manual). Mount the required indenter in the indenter holder using the set screw on the side of the holder. Test Procedure4.3 The UCI hardness test may be used on large or small components at various locations. It can be used to make hardness measurements on positions difficult to access, such as tooth flanks or roots of gears. A. GENERAL DESCRIPTION OF INSTRUMENTS AND TEST PROCEDURE FOR UCI HARDNESS TESTING 5. Apparatus 5.1 Instruments used for UCI hardness .Standard additions method (sample spike)—0.020 N titrant Use the standard additions method to validate the test procedure, reagents, apparatus, technique and to find if there is an interference in the sample. Items to collect: • Calcium Hardness Standard Solution, 10,000 mg/L as CaCO3, 10-mL Voluette ampule • Ampule Breaker

The Vickers hardness test is ideal for testing of all metals and is therefore the method with the widest range of application. The hardness test method according to Vickers is described in standards ISO 6507 (Metallic materials – Vickers hardness test – Part 1: Test method) and ASTM E384 (Standard Test Method for Microindentation Hardness (1gf - 200 gf) of Materials .2.2 Testing principle 12 3 Technical capabilities 12 3.1 Specifications 12 3.2 Dimension size and weight 13 4 Testing 13 4.1 Preparation and Inspection prior to testing 13 4.2 Testing 15 5 Special prompts 18 6 Detail Testing procedures 19 6.1 Start-up 19 6.2 Turn on or turn off 19 6.3 Testing 19 6.4 Menu structure diagram 22

hrc hardness testing

hardness testing methods

webYonna Galvao’s modelling career has flourished, propelling her to a successful position with a net worth of around 120k USD. Her strong online presence complements her achievements in the fashion industry. As her career continues to thrive, experts anticipate her influence and financial success will escalate even further.

dot hardness testing procedure pdf|hardness test results